A Saw Stool on Steriods!

Those who have worked with me know how much I value traditional Saw Stools. I use them in the workshop and out on the job all the time. In fact I am lost without them! I usually have several sets, some low ones at around 21” high and some taller ones at 30” high.

I am not talking about those crappy folding metal and pine things, which wobble around and carry warning stickers saying you should not stand on then. I am referring to properly made traditional saw stools. Traditionally made from jarrah in Western Australia, these are rigid and can carry considerable loads. I have in use some that are well over 50 years old and which have worked hard all their lives. These type of saw stools were standard equipment for carpenters, joiners and cabinet makers for generations.

I had a big job to do recently, which involved working on site in Kalamunda for 3 weeks solid. I took a portable jarrah work bench with me, as there was a fair bit of bench work to do over those 3 weeks. Of course I also needed to use 2 pairs of low saw stools and 2 pairs of taller saw stools on site for that period as well.

While I worked on the job, I got thinking: How can I create a saw stool X workbench hybrid, which would be more portable than my portable work bench?

So I have played with the idea, and the result is a Saw Stool which looks like it has been on steroids:

View of the beast – a hybrid between a saw stool and a bench.

View of the beast – a hybrid between a saw stool and a bench.Here are the specifications:

Height: 880mm. The legs have a 10 degree splay to the ends and to the sides.

Length: 980 (plus tail vice outer cheek equals 1030mm overall.

Width: Pine 220mm, including jarrah front edge equals 260mm.

Tail vice: Maximum bite 240mm

· Minumum bite between dog holes: 240mm

· Maximum bite between dog holes: 1040mm.

Front vice: Maximum bite 140mm

· Minimum bite between dog holes: 110mm

· Maximum bite between dog holes: 390mm.

Almost whole thing is made from recycled salvage material :

· Pine top – from a 10” x 3” solid pine beam.

· Legs, rails, and other odds and sods – from some 3”x2” jarrah wall studs.

· “Breadboard ends” – from an old jarrah door sill. · Jaw cheeks of the front and tail vices – from a jarrah 8”x2” ceiling joist.

· Vice handles made from Peppermint (Agonis flexuosa) I milled years ago.

· Tail vice guide rod made from a piece of Tuart (Eucalyptus gomphocephala) leftover from the making of the Endeavour Replica.

· The tail vice screw and front vice are those imported ones from China or Taiwan, bought from my local woodworking shop. The front vice is the smaller of the two models available locally, and is pretty disappointing. Its guide rods and screw are not square to the metal vice front and rear, and are barely parallel. However the tail vice screw is a ripper. These metal components cost less than $100 in total. I put the additional bit of jarrah onto the front side of the pine to beef up the work area a bit and provide a more durable front edge to the work area. The only reason I used pine was to help keep down the weight!

This job involved removing a customer’s front entry joinery, then installing and modifying a beautiful old piece of art deco joinery obtained from a demolished building and adding two more art deco side light sashes either side. This involved lots of tricky hand work on site, where the beast proved to be invaluable.

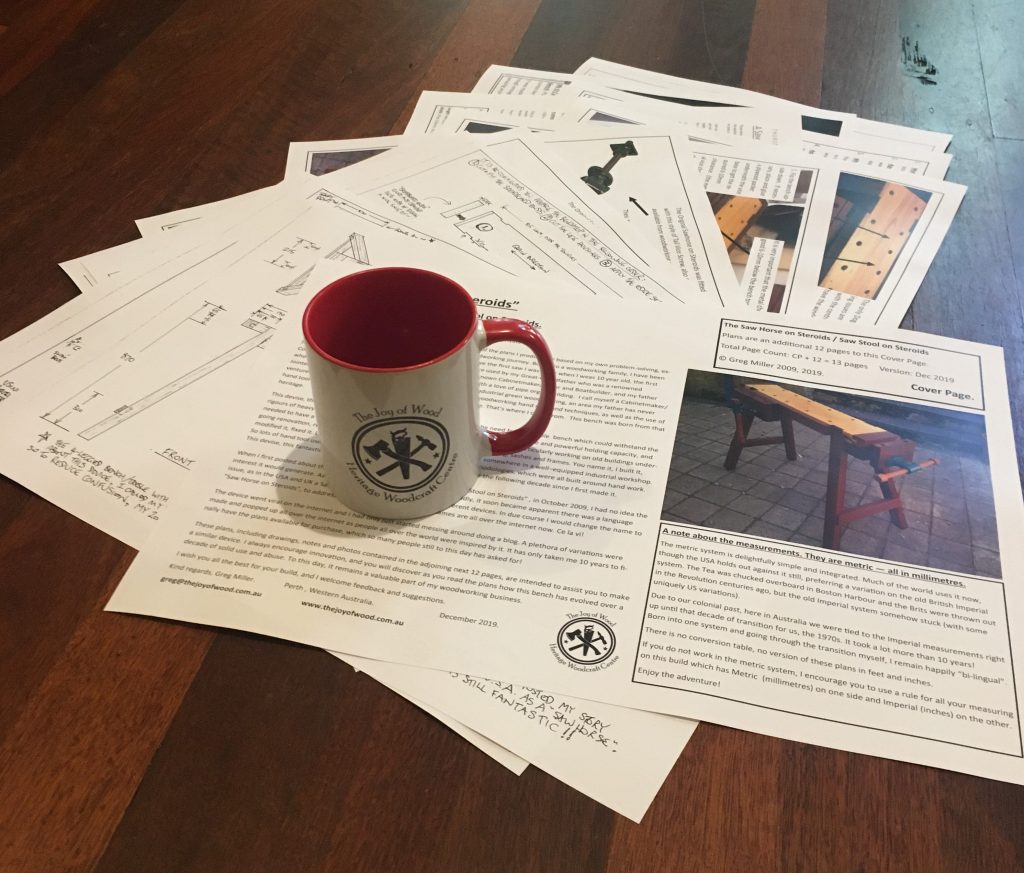

December 2019…PLANS ARE NOW AVAILABLE FOR PURCHASE! Please go to our ETSY store: https://www.etsy.com/au/shop/TheJoyofWoodStore

I want to make one!

Just lovely, thanks for sharing.

Once again I realise time is a valuable resource I need to create more of….

Looks a great piece of kit. I must make one of these!..thank you for the idea Greg…

This is really cool and I am going to try to make one.

Great idea, Sergio. I would love to see a photo when you have finished it!

Hi Greg, I am currently building a Steroid Stool basically as per your design, but without the tail vice. Questions: how far from the ground should I put the spreaders on the legs? Could you post some pics of the horse + removable shelf?

Awesome. My next project!

Very nice, the legs and the top are joined with a sort dovetail joint (without glue)?

where can I buy the plans

Gidday. I am working on drawing up the plans at the moment (a few years late), and hopefully they will be available for sale sometime soon!

How’s progress on the plans? Very interested in buying a set

slow but steady… hopefully soon!

That looks like a really tidy piece of kit! I'm only just starting to get in to woodworking but I can already tell how super handy it'd be! I'd love to be able to try my hand at putting one together if you put some plans up…

Hellou, i'm from Argentina and very interested to see plans, is psible?

Sorry for my english.

Congratulations and thanks,

Mike

I am interested too !

Very nice, what kind of finish did you apply? regards.

Mr. Miller, thanks for your great wood work, I'll make one like yours.

Please, let us know when your drawings are finished. I'm very interested to make one.